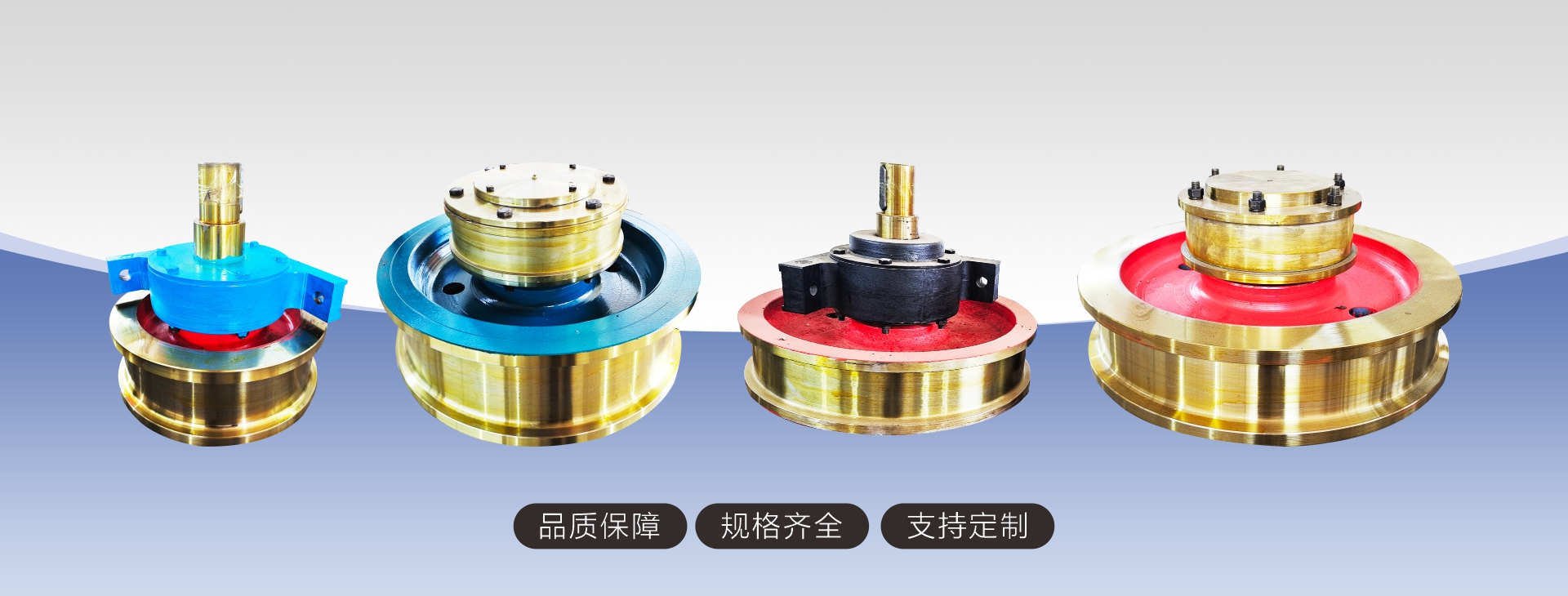

起重机车轮组:起重机运行机构车轮的水平偏斜值是起重机重要的技术参数,偏斜值超差会造成啃轨,增大运行阻力,产生振动和噪音,加剧轨道和车轮磨损,大大降低起重机使用寿命,所以各类起重机制造技术条件都要对车轮水平偏斜规定允许的数值。应用中控制运行机构车轮水平偏斜值主要是根据不同的产品结构采取相应的技术措施。比较常用、工艺措施也相对简单的设计结构是:将车轮装配到支架上组成车轮组,例如角型轴承箱车轮组和台车式45°剖分轴承箱车轮组,在起重机主结构上,安装调整车轮水平偏斜合适后固定。Crane wheel group: The horizontal deflection value of the wheel of the crane operating mechanism is an important technical parameter of the crane. The deviation value exceeding the tolerance will cause rail gnawing, increase the running resistance, generate vibration and noise, intensify the rail and wheel wear, and greatly reduce the service life of the crane. Therefore, the manufacturing technical conditions of all types of cranes should specify the allowable value of the wheel horizontal deflection. In application, the control of the horizontal deflection value of the wheels of the running mechanism is mainly to take corresponding technical measures according to different product structures. The design structure with relatively common and relatively simple technological measures is to assemble the wheel onto the bracket to form a wheel group, such as the wheel group of angle bearing box and the wheel group of trolley type 45 ° split bearing box. On the main structure of the crane, install and adjust the horizontal deviation of the wheel and then fix it.